charpy impact test percent shear|charpy impact cheat sheet : manufacture Figure 2-1: Charpy impact tester, sample positioned in anvil and general testing results. This test has been used almost exclusively with body-centered-cubic (bcc) crystalline materials. These . webMega Lanches Rua Simão Tamm, 98, Belo Horizonte, MG Fechado para pedidos 90-110min Mínimo R$16,90 Ver Mais 01- Sanduíches; 02- Acréscimos Sanduíche; 03- Pizzas; 04- Acréscimos Pizza; 06- Entradas; .

{plog:ftitle_list}

Resultado da Localizada no Estádio Morumbi, a Companhia Athletica - Estádio Morumbi é a escolha certa se você procura uma academia com serviço completo. .

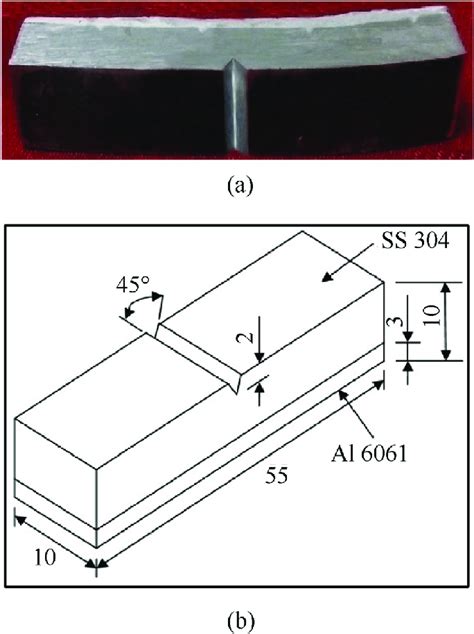

charpy test sample dimensions

In a Charpy impact test, three key measurements are typically made: total absorbed energy, lateral expansion, and percent shear fracture area.

charpy impact test standard pdf

As a result of its widespread use, there is a compelling motivation to extract as much data as possible from the Charpy test. In a Charpy impact test, three key measurements are typically .Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact .

Figure 2-1: Charpy impact tester, sample positioned in anvil and general testing results. This test has been used almost exclusively with body-centered-cubic (bcc) crystalline materials. These .ABSTRACT: This paper provides a broad overview of the progress in procedural improvements for Charpy impact testing. It includes a short summary of early developments, a discussion of .Some Charpy test standards require the percentage crystallinity (brittle fracture appearance), to be quantified in the test results, whereas others give the percentage shear area (ductile .

Percentage crystallinity is simply the inverse of percentage shear area, assuming that the Charpy specimen fractures purely in a mixture of brittle and ductile failure modes. A brittle .

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a .Shear and Lateral Expansion. Shear: Percent shear in a charpy impact test is a measurement of the amount of brittle and ductile fracture in a broken specimen’s fracture face. Lateral .

charpy impact test specimen size

charpy impact test specimen

testo 320 basic flue gas analyzer

The Charpy impact test is particularly essential for materials used in parts that are subjected to strong impact or high pressure, such as those used in the power generation units and piping of nuclear power plants. . The percentage of .

Charpy V-notch impact test is used to determine the V-notch toughness of a metallic material according to the absorbed amount of energy for fracturing. From: Cryogenic Valves for Liquefied Natural Gas Plants, 2022. . Percentage crystallinity is simply the inverse of percentage shear area, assuming that the Charpy specimen fractures purely in .

The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. . When reporting the .Percent Shear Area Determination in Charpy Impact Testing M. P. Manahan, Jr.*, C. N. McCowan**, and M.P. Manahan, Sr.* Abstract: The Charpy test is used throughout the world in a wide range of industries because of . the percent shear fracture by means of a planimeter. 4. Photograph the fracture surface at a suitable magnification and measure .

FIG. 9—Example showing outlines for the brittle and total fracture areas for a test specimen with a large crack normal to the primary plane of fracture. - "Percent Shear Area Determination in Charpy Impact Testing"The percent shear area on the fracture surface of a charpy impact specimen typically calculated as the difference between the total fractured area (Fracture Initiation Region, Unstable Fracture region, Shear Lips, and Final Fracture Region) and the unstable fracture area, divided by he total fractured area, times 100.

Impact test. Measures the ability of a material to absorb a sudden application of a load without breaking. The Charpy test is a commonly used impact test. Lateral expansion. The lateral change in dimension of a Charpy impact specimen due to fracture. The dimension measured is the width opposite the v-notch (see Fig. 1-3).Percentage crystallinity is simply the inverse of percentage shear area, assuming that the Charpy specimen fractures purely in a mixture of brittle and ductile failure modes. A brittle material when Charpy tested makes a ‘ting’ sound and the striker swings up fairly high after the test. . Modeling the Charpy impact test is a challenging .The Charpy impact test was invented in 1900 by Georges Augustin Albert Charpy (1865–1945), and it is regarded as one of the most commonly used test to evaluate the relative toughness of a material in a fast and economic way. The Charpy impact test measures the energy absorbed by a standard notched specimen while breaking under an impact load. This test continues to be .

The Charpy impact specimens of each material are immersed in a bath for 10 minu tes to reach thermal equilibrium at five separate temperatures ranging from 110oF (-79oC) to 212-oF (100oC). The specimens are quickly transferred to the Charpy testing machine, fractured, and the impact energy is measured. AfterKEyw0R)Crs: Qqy impact testing, verification, 2-mm striker, 8-mm lateral expansion, inst%rnented striker, energy, percent shear, standard deviation, plate, weld, forging Charpy V-notch (CVN) impact testing is performed by hundreds of organizations around the world using very similar procedures, usually either that of the American society for Testing and Materials . ASTM E2248 – 18: Standard Test Method for Impact Testing of Miniaturized Charpy V-notch Specimens.; Ductile to brittle transition in impact testing. Carbon steel and low alloy steel are characterized by the fact that the fracture behavior changes as the temperature drops and the fracture type changes from ductility to brittleness.

FIG. 1—“Textbook” fracture surface showing bright, shiny, faceted region surrounded by ductile fracture area. - "Percent Shear Area Determination in Charpy Impact Testing" What Is the History of the Charpy Impact Test? The Charpy impact test, introduced by Georges Augustin Albert Charpy (1865–1945) in 1901, is widely utilized for efficiently evaluating the toughness of materials. This method assesses the energy absorbed by a standard notched specimen when it fractures under an impact load.where y is Charpy energy (or lateral expansion or percent shear), T is temperature, and a 1 are the model parameters to be determined by fitting. The parameters can be interpreted as follows: a 1 is the lower shelf value of y; a 2 is the upper shelf value of y; a 3 is the temperature at which the hyperbolic tangent function has its inflection point; and a 4 is a measure of the temperature .

The Charpy impact test is a commercial quality control test for steels and other alloys used in the construction of metallic structures . the equation for percent shear fracture, PSF3, gives the .

Shear: Percent shear in a charpy impact test is a measurement of the amount of brittle and ductile fracture in a broken specimen’s fracture face. Lateral Expansion: Lateral expansion is a measure of the ductility of the material. It refers to the increase in width of the specimen at the point of impact. High lateral expansion values indicate .

Percent Shear Area Determination in Charpy Impact Testing M. P. Manahan, Jr.*, C. N. McCowan**, and M.P. Manahan, Sr.* Abstract: The Charpy test is used throughout the world in a wide range of industries because of . the percent shear fracture by means of a planimeter. 4. Photograph the fracture surface at a suitable magnification and measure .Charpy impact testing on metal to ASTM E23. Charpy V-notch verification. Calibrated impact testing equipment. Fast & Accurate results. Call 1-888-611-3076. Metal Testing Laboratory. Home Metal Testing . Often shear percentage is measured using the "eyeball" method. We have developed a way to quickly and accurately evaluate shear using a .

CONTACT US. Contact: Tamas Vibranyec. Phone: 0086-0579-7963961. Tel: 0086-0579-7963961. Email: [email protected] Add: No. 1336.Bingwang Road Street,Yiwu City Zhejiang . Test criteria for Charpy V-notch impact testing usually involve (i) a minimum impact energy value, (ii) shear appearance of fractured test bars expressed in percent, and (iii) lateral expansion. For steels, the minimum acceptable values generally specified for these three evaluation methods are 20 J, 50 % shear, and 1.3 mm respectively.original focus of the pendulum machine was on the measurement of absorbed energy [3, 4]. Other parameters from the Charpy test, in particular lateral expansion and percent shear, were investigated much later. Historical Perspective on the Use of Percent Shear No seminal paper identifying shear area as a key Charpy parameter was found in the literature search for this .

This paper was submitted to the Journal of ASTM International in January, 2008. It is currently being peer reviewed. Percent Shear Area Determination in Charpy Impact Testing M. P. Manahan, Jr.*, C. N. McCowan**, and M.P. Manahan, Sr.* Abstract: The Charpy test is used throughout the world in a wide range of industries because of its low cost and the fact that . Load-time traces from the instrumented strikers were also compared and used to estimate shear fracture percentage. Four different formulas from the European Structural Integrity Society draft standard for instrumented Charpy test are compared and a new formula is proposed for estimation of percent shear from the force-time trace. The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is abruptly subjected to bending stress. The specimen is usually 55 mm long and has a square cross-section with an edge length of 10 mm.The Charpy impact test was performed after extracting samples in directions both parallel and perpendicular to the deposition direction. . Manahan, M.P.; Mccowan, C.N. Percent Shear Area Determination in Charpy Impact Testing. J. ASTM Int. 2008, 5, 101662–101676. [Google Scholar] Parrington, R.J. Fractographic features in metals and .

Standard Test Methods for Notched Bar Impact Testing of Metallic Materials,5 and ISO 148-2, Metallic Materials – Charpy Pendulum Impact Test – Part 1: Test Method,7 consists of a physical part (direct verification) and an experimental part (indirect verification). The direct verification consists in the detailed evaluation of

charpy impact test sample dimensions

charpy impact test sample

Lésbicas se pegando na balada 2 min. 2 min Cameracaseira .

charpy impact test percent shear|charpy impact cheat sheet